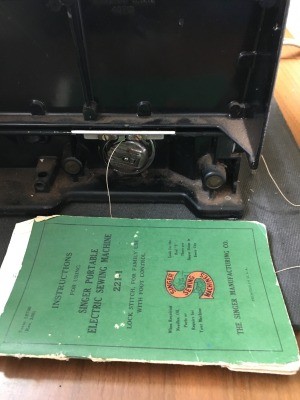

My mom's trusty Singer 221-1's bobbin will not catch upper thread from needle. I can't catch the bobbin and pull it through. What is mechanically not happening below with bobbin mechanism?

My mom's trusty Singer 221-1's bobbin will not catch upper thread from needle. I can't catch the bobbin and pull it through. What is mechanically not happening below with bobbin mechanism?

Normally when this happens there is a lot of lint, dust, and dirt in this area that needs to be cleaned out. Also, it could be that the canister for the bobbin is not threaded correctly and this causes an issue. I would start off by removing the canister, unlatching the holder for the canister, and checking this area for lint and dirt. There is normally a lot of this in the area that needs a small brush to clean it out and get all the lint out of there. Then put this back together. Make sure you have the canister threaded correctly where the bobbin in place in there the right way and you go through the small opening and pulling the thread to the larger opening.

This is a Featherweight Singer and not everything works exactly the same way as some other models.

Have your or your mother used the machine lately with no problems?

Singer has the most extensive self help information of any type of machine so be sure and take advantage of their work shops. These sites have suggestions as well as videos so check them out as sometimes seeing a job preformed is easier than reading about it.

www.singer.com/

singer-featherweight.com/

singer-featherweight.com/

If still having problems or have other problems in the future; the following sites have forums and these members will help solve any sewing problem.

sewing.patternreview.com/

www.quiltingboard.com/

Ask a QuestionHere are the questions asked by community members. Read on to see the answers provided by the ThriftyFun community or ask a new question.

I have kindly been given a Singer 447 machine. I set it up and it was working fine for a while, but now it won't pick up the bottom thread. I have re-threaded and check the bobbin.

With the plate off I can see that the bottom bobbin does not seem to be moving. Does anyone have any suggestions on how to fix this? Thanks.What you are describing is a worn bobbin gear. This is not a 'home-fix' job as it requires specialised tools and knowledge. I do a lot of bobbin gear replacements for my Sewing 101 students over here in Scotland - you should be sure any repair tech you use tells you (and shows you) if he/she is using a salvage part, or was able to find a 'new-milled' replacement. The salvage parts often come from machines with unknown sewing histories and many machine owners are disappointed when the salvage part fails sooner rather than later.

I usually do one replacement, telling the student his/her machine had to be repaired using a salvage part, and advising when it fails, the best thing is to retire the vintage Singer and buy a comparable new one under warranty.

To keep your machine working properly you must always pull out the thread of the bobbin by hand and place it with the upper thread under the foot and behind the foot before you start sewing. To catch the bobbin thread you move the hand wheel by hand to let the needle go down and up again while holding the needle thread and you catch the little loop that comes up with a needle. To solve your problem you could try to change the needle or check that it did not move in the needle holder because if the needle is too short or too long it can't catch the bobbin thread.

I have a very clean Singer 301. I am using 50 wt. cotton thread top and bobbin. I have a new needle, inserted correctly. The bobbin is in correctly. It sews a fine straight stitch, but when the regular presser foot is removed it won't pick up the bobbin thread. It looks like the timing is good. I am remembering to put the presser foot down. The feed dogs are down. The stitch length is set to zero. The tension seems fine on straight stitching. Nothing looks broken. It just won't free motion quilt.

By Alyce L.

Three questions - have you lowered the feed dogs (or covered them with the handy snap-down plate), are you using a specialty foot for free motion quilting (sewing machines recognise the foot and behave accordingly - without the specialty foot you may not be able to do this kind of stitching), and have you tried setting your stitch width and length one notch up from zero?

I know you want to thread paint (quicker than saying free-motion quilting) using a straight stitch but with my Singers (Talent 3321, treadle 66 and handcrank 99) I have to nudge the stitch width and length a hair up from zero. Yours might be the same.

Also, what does your owner manual say about free-motion darning? Are you following the set-up directions for that function (essential for thread painting).

If those two questions are either a yes or don't help, I'm flummoxed! You should be able to do this kind of stitching on your 301, you might want to check with a repair tech or sewing instructor face-to-face who can 'fiddle' with it to see what the problem is.

When you find out, will you please update this? You can't be the only sewer-quilter who's had to figure this one out so your update will help a fellow sewer!

Hi! I just finally got my 301 set correctly in order to free motion quilt. I was having issues with tension as well as with skipped stitches.

Lower the feeds dogs, set stitch length to 0 which is just above the highest # stitches, make sure you have a darning foot that fits the machine. Then increase the presser bar tension. The darning foot will press down hard while making the stitch and then release so you can move the fabric between stitches. The fabric needs to be held in place during the stitch making otherwise it won't catch the bobbin thread.

the 301 manual shows using the darning foot with the fabric in an embroidery hoop, but if you use a darning foot with the presser bar set to really hold the fabric taut during stitch making then you should be fine.

Let me know if you need more help. I went from bonkers frustrated to being able to do this and I know you can, too.

I have the same problem with the bobbin thread not coming up. I do NOT have a darning foot... which could be the problem. Do they still sell feet for 301 slant shank?

I have a Singer 338 which straight stitches absolutely fine. Followed all the manual instructions to free motion but it just won't stitch the fabric. It pulls the thread up to the top but once I start to stitch the fabric it stops creating the loop to stitch. The manual doesn't mention needing a darning foot at all.

My machine will not catch the bobbin thread. I can feel the gear below moving and it pushes up on the bobbin and when I first pulled the bobbin out the holder seemed to not be in the correct place. Is this something I can fix or do I need to take it to a repairman?

This is a borrowed machine, a Singer Stylist 418. I have a model similar to this but a few years newer. They operate basically the same. My problem is with the bobbin. The needle will not pick up the thread....nothing. The bobbin was almost empty, and the thread caught inside the bobbin area. It would not come out, I pulled it hard and it broke off. I rewound a new bobbin, and the needle, unlike my machine, went up and down during the winding process.

Now, it will not pick up the thread. I changed the needle, adjusted the needle, re-threaded the machine several times, the bobbin is in correctly. I took out the bobbin housing and removed the little piece of thread left in the area. Any advice from someone?First, here's a link to a free user manual download from the Singer website:

www.singerco.com/

Use the troubleshooting pages at the back of the booklet to see if there is any helpful tips you can use - I don't think you'll find any help there, though, because after years of repairing vintage Singers including Stylists (usually the 513), I can say with near 100% certainty that the problem is a worn bobbin gear. These were made with silicone during the Stylist years (late 60s through mid-late 80s). Replacing one isn't a home fix - you need to take the machine to a repair tech.

I could be wrong - it could be a stubborn piece of thread or fluff has lodged somewhere you can't see, or it could be a couple of other things - the only person who can get this machine back to sewing condition is a repair tech with the machine on his/her bench so it can be properly checked.

Be warned - with the Stylist line, once the bobbin gear goes and needs to be replaced, other parts start to go as well, and it doesn't take very long for the machine to become a 'money pit'. As you've borrowed the machine, you're the unlucky person using it at the time the part 'died' and are therefore honour bound to have it fixed. This part gives no warning, it just goes when it goes, and you were the one on it when it did - nothing you did wrong, it's just Time having its way with the machine. Have it fixed and then never borrow it again because it's only a matter of sooner rather than later before another of the silicone parts fails.

Thanks so much for your response. I agree, a tech/repairman is the way to go. I do feel honor bound to have it repaired as my friend was so generous to loan it to me. It was running great prior to this incident. I was trying to get a seat cushion done on a glider rocker for my daughter who is expecting a baby any time. I put out calls to other friends for a loaner, and ended up with a 1949 Singer Featherweight. You may know it, the little back machine in a cute black case. Apparently, it had not been used in 30-40 years. Well, I love American ingenuity! It was a little musty, but that little wiz came out of the carrier and purred like a kitten. The bulb shown brightly and I finished the cushion. I wish it were mine!! Thanks again!

Bonnepm, thank-you for your update! The Stylist was (is when still operational:) such a great sewing machine, it was one of the few 'domestic' Singers that made as good a straight stitch as a zig-zag - many machines (not just Singers) do one or the other beautifully but not both - on a zig-zag machine the straight stitch is never really-really-really true straight. But the Stylist line could go from straight (true straight!) to z-z and right back to a true straight. Bliss, really, for home sewers. I loved my 513 so much I kept it going yonks past its use-by date! Finally, though, it became a very real money pit. When that bobbin gear goes everything seems to go.

But wow-wow-wow, to be lent a '49 Featherweight is amazing! All metal gears, it's really hard to 'kill' a pre-60s Singer and a Featherweight to most of us vintage enthusiasts is the pinnacle of Singer sewing machine ingenuity. I don't blame you for wishing it could be yours, I wish I could find one myself:)

Best wishes for a safe delivery of a beautiful healthy baby for your daughter!

I have a Singer sewing machine model 4525C and a model 9022. The needle thread is not picking up the bobbin thread on either machine. The shuttle(?) Is catching the needle thread and taking it around, but it isn't catching the bobbin thread. It is a top-loading bobbin on both machines.

Please help. Thanks.

My Singer 7422 Advanced portable machine locked up when I was trying to use the zig-zag stitch for repair on denim fabric shorts. I had to cut the material/thread loose. It sounded like it was hitting something. I re-threaded the machine and it will not pickup the bobbin thread. I have tried to locate a manual on line. I can't even remember when I purchased this now discontinued model. Any suggestions upon a possible repair?

Two weeks ago I brought a new Singer sewing machine and an older 1960s machine to the Caribbean to help a small community. I bought both from a Singer dealer in Montreal. I thought the older model would be a good strong backup as the newer ones are more difficult to take apart and fix. I was wrong. The older machine won't pick up the bobbin thread. The local fix it guys identified the problem as the yellowish piece in the photos. They say it is worn and won't grab the metal piece properly and they have seen several machines here, now unusable with the same problem. They have tried to source the piece in the USA with no success. Any ideas?

I will write to the Mr. Sewing Machine in Montreal who sold me the old and the new machine plus the older machine (as well as my personal machine that I bought new a few years ago). I am about to write him as I have friends coming down who can bring the part if he is willing to solve this, but he may want me to drag it back to Canada instead. I paid almost as much for the old one as the new one, never dreaming it would have an unreplaceable part.

Really wish I had contacted a Singer sales representative or their PR department before I left Canada, but I got busy with an illness in the family and had to discard some tasks on my to do list due to an illness in the family. So my second question is whether anyone has a contact at Singer who might have philanthropic tendencies. If I didn't have a personal investment in two new Singer machines, I would be hesitant to contact Singer, but.

As a point of internet my home is by Singer Mountain (Ruiter Brook Rd. QC- Ruiter Valley) where the wood for the vintage wooden singer sewing machines was logged. You can see Ruiter identified on the metal tags on those vintage singer sewing machine stands.

It is now March 8, 2019 and I am here until April 3, 2019.

To summarize:

1) is this really the problem

2) if so, if the vendor doesn't help me, is there any hope of getting the part in any marketplace (if so I would also buy the parts for the other poor souls here with useless machines)

3) any contact info for philanthropy at Singer

4) should I just bring the machine back to Canada (sad faces here) and do more homework next year.

Thanks.

I have a little Sew and See machine I ordered from Walmart and it's not seeming to catch the bobbin thread. This is my first time ever using a sewing machine so I chose to get a tiny one, but I'm not understanding why it won't catch.

I've done everything in these answers and nothing is helping. Can someone help me please?I bought this Singer 413 recently. It was sewing just fine then the needle broke. I replaced it with an identical needle, but now I can't get the bobbin thread to come up through the plate.

I just recently got a Singer Tradition 2259 to start off. Everything was working fine until my first project got jammed. It took a while to free everything, but now my bobbin thread won't raise and my upper thread is just staying down below. I've changed the needle and cleaned out any dust or anything. Please help!

By babylexi

Make sure you don't have the bobbin in upside down. Because what you are describing is what mine does if its upside down or backwards.