So I was sewing a quilt and then all the sudden it threw me a code (E5). I looked in the manual, searched online, etc. nothing came up for it. I called Singer and they told me how to troubleshootthe machine, being that it could be the motor and the nearest place for me to send it to would be in Kansas and I would have to pay for shipping to and from and labor.

My machine is 3 years old and is used lightly compared to most, so I can't completely wrap my head around why it would be the motor to begin with. I did the reset and it worked for about 2.5 seconds after I hung up the phone. My question is if it is the motor should I buy another one and replace it myself, or just buy a new machine for the same price as shipping the one I have to Kansas?

Also, I have a Brother limited edition Project Runway that a friend let me borrow so I can finish my projects, but it didn't have a pedal. I used a Singer pedal and when I stepped on the foot pedal nothing happened, as soon as I let off, the machine goes full speed and doesn't stop at all, it won't let the fabric move either. I had to shut the power off in order to get it to stop and the bobbin case is clunked with thread. TIA if anyone can help.

As far as the Brother machine..it might not be compatible with a Singer foot pedal, or your E5 error code on the Singer could be the quoted problem in my first answer. Please check your foot pedal before going to the trouble and expense of a repair shop.

Before deciding on throwing the machine away, fixing it, or looking for a new one you should check all the connections of the machine. You could have a simple problem that the foot pedal is not connected to the machine correctly. This could also be an issue with the foot pedal of the machine. Normally this goes out and when connected and turned on it could give you the same error code. If the reset worked for a minute or two I would check all your connections and make sure they are secure and try it again.

As for the other machine not working when you have used a different foot pedal this one is extremely possible. The foot pedals are wired for each machine and if you try switching them around you can find the issue you are talking about. If you borrowed the machine please ask your friend for the foot pedal and try again.

If the machine motor is really gone you are probably correct by the time you pay for the repairs on the machine you could have bought a brand new one for less.

This could be your connectors , such as loose power cord, damaged power cord, cord to pressure foot pedal . Anything loose or failing can give this code. Try adjusting and making sure electrical cord is secure and not damaged and not to much tension on cord.

Here are the questions asked by community members. Read on to see the answers provided by the ThriftyFun community.

I have a Singer 7258 sewing machine. When trying to wind the bobbin, it stops after just a second and shows error code E2. It looks like the needle is not disengaging.

Does anyone know how to fix this? I'm heartbroken. I have been waiting 3 years to start quilting for my grandchildren. Thank you!The error code is for a bobbin error that means it is in the machine wrong. Here is a trouble shooting guide that will walk you through all the steps to get the bobbin in the machine correctly and get rid of the error code.

My buttonhole foot won't make buttonholes. I have all the settings right, in the correct order. All I get is a glob of thread. The foot doesn't move like it should to make the buttonhole.

Has anyone else had this issue?

I am looking at buying a vintage singer 467 sewing machine but the reverse buttom is not working. I was told that it is sewing in reverse only. The button is loose and can be pulled in and out. Is this easy to fix?

First of all clean/oil the machine to see if that helps. A spring may also need to be reattached or replaced. You might also try using a hair drier & blowing hot air towards the reverse button for a few minutes to possibly loosen it up. Here are some other things that may help:

I have a Singer 600E, I've threaded the bobbin and all that good stuff. But when I push my pedal down my needle won't move, the motor runs, but nothing happens. Is it my pedal?

Sorry if my answer is a bit too simple but the motor runs and the needle doesn't move when you thread a bobbin so maybe you left the machine in that special position, usually it is a special position of the handwheel.

Hope this helps !

I bought a vintage Japanese badged Singer zigzag machine. It sewed beautifully, but I couldn't get it in reverse. So I removed the stitch regulator button as this is part of it, to see if the reverse button was frozen. When I put it back together, now it won't sew forward unless I hold the reverse button. The feed dogs don't move unless I hold it in.

When I hold the reverse button in it sews forward and has very nice stitches. If I don't hold the reverse button in the feed dogs don't move and the reverse button goes in and out as if I'm sewing. I know I didn't break anything, but feel something is misaligned now.

You have replaced the parts wrong in the machine and put the control button back in backwards. Now the machine setting think you are sewing in reverse which is not correct and that is why you must hold the button in to make it sew forward. This part is bad on the machine and needs to be replaced in order to fix the problem. You need to take the machine apart again and look how you assemble it. Make sure you have it assembled correctly and if you do it should sew again forward but it will not sew in reverse because the part is bad.

I think the original problem was that you needed a new part as the reverse would not work. When you took it apart you probably did not get everything properly set or the part that was bad has just gotten worse - but it does sound like you placed something incorrectly as you are telling your machine to do something that it cannot do - without your help (these parts are tricky to get just right).

It sounds like you have a manual that you were trying to follow so that is good but still not easy unless you have experience.

If it were my machine, I would try to take it to a shop and ask for help but not a full service job - be sure they know this before they touch your machine.

Be very sure they tell what it will cost for them to tell you what you need before they look at your machine.

You only wish to know what part you need and buy it from them unless you think the price is too high.

I always go to the Sears Service Center as they have helped me many times and only charged for the parts I needed. They work on all models/brands.

The machine is heavy but you will probably have to do this sooner or later.

I'm a newbie at sewing and I'm having a problem with my sewing machine. It is a Singer 6215c. It worked great before until last week. It sews, but is somehow stuck on the shortest stitch length. The knob moves, but the machine would only sew with shortest length even with the knob pointed on the longest stitch length.

I have checked the tension, rethreaded several times, checked bobbin, and dusted the areas accessible, but the problem still persists. Thank you.

This happened to my 'white' sewing machine, the only way to repair it is to take it to the repair place, there is apparently a gear that falls off inside the machine and it it is not easy for someone who has no experience to repair. I am fortunate as my son-in-law used to fix sewing machines for a living.

First: check your user guide manual to be sure you have ALL of the settings correct. Here's a link to a free download from the Singer website (USA) for the Singer 6215, pay especial attention to page 14 and the troubleshooting page 41:

www.singerco.com/

Your machine was built in the early 1980s making it a definite 'vintage' machine with most of the gears made with silicone, rubber, and plastics for the gear 'teeth'. Over time these materials wear down, crumble, and snap off, and it sounds to me as though that is the problem with your vintage Singer.

The previous poster is right - you need to take this to someone with experience and training (a professional or a 'self-taught' repair tech with a sterling reputation). Not only is this a tricky repair, it requires specialised tools and access to parts.

Not all vintage sewing machine parts are 'new-milled', too, and with a vintage machine it's common for a repair tech to have to use 'salvage parts' with unknown sewing hours and conditions - the part may look fab but has been stressed by sewing conditions (too fast seaming, lack of regular maintenance, dusty sewing area, more) - with a salvage part no repair tech worth his or her salt can make a prediction as to the longevity of that part.

Be sure to ask your tech if he/she is using salvage parts on your repair, and make sure he/she does a servicing on it whilst in their workshop - cleaning, oiling, and checking for potential problems. With vintage machines, an annual servicing is the only way to ensure sewing hours reliability.

Once parts begin to break down on a machine it becomes a money pit even if new-milled parts are available, btw. Consider replacing your vintage with a comparable new machine under warranty. A good repair tech will fall in love with your vintage machine but will also tell you about the money pit factor and will recommend a new under warranty machine.

I live in Scotland after 50+years in the US; I teach sewing and do limited vintage machine repairs. When one of my students brings me a vintage machine that has sadly become a money pit I usually recommend the 3321 with the 4-step buttonholer or 3323 with the one-step buttonholer Talent line as these are fairly user-friendly with good features that aren't quickly outgrown, are comparable to your vintage 6215, and reasonably priced. The Confidence line is a step-up but doesn't have the same reliability reputation as the Talent line.

Do your research and whatever you do, be sure to choose a machine with a top drop-in bobbin for ease of use and virtually jam-proof sewing.

The needle bar on my Singer Stylist 413 has become loose and I can't figure out how to fix it. It doesn't stay in place and I can literally turn the needle back and forth. I had to adjust the needle bar to align the machine marks with the bottom of the casing after I had replaced the vertical gear (which broke into pieces) and reset the hook timing. Ever since, I can't seem to get the needle bar to stay securely in place. Can anyone help? I also can't find a repair manual for my machine. Thank you.

Sometimes repairs are not as simple as just looking at a diagram and you may need a video or someone to walk you through your repair.

If you are in need of a manual for your machine this site has a free downloadable copy.

www.singerco.com/

My Singer Brilliance 6199 sewing machine is displaying E7 code.

Singer 185k rehab runs great. Now when I sew, I can't regulate stitch length and the fabric seems to pucker slightly. I had to reset presser foot and feed dogs, also had to clean thread tension unit.

I really would like your thoughts on why it won't sew normally. Stitches seem normal. Appreciate any help fixing these problemsThis is a neat machine but a friend says hers is different than any of her other Singers and she is always having to ask sites for help when 'something' goes wrong.

I found a lot of information online but you may need to ask for help with your problem.

Check out these sites:

Best site to ask for help with any model machine or any problem:

www.quiltingboard.com/

Link to free manual:

singerco.com.au/

All of these sites have information about your machine and also supply names/models of other machines that are the same or near the same as your machine. This information will help you if you ever have to have parts for your machine.

Each site has loads of information and usually a link to ask questions:

www.singersewinginfo.co.uk/

mermaidsden.com/

mermaidsden.com/

www.reddit.com/

Stitch length adjustment only will eliminate the puckered seams as well as the entire stitch appearance. The old Singer sewing machines cant make long stitches, the range is for the number of stitches per inch. Hence, the bigger the number, the smaller is the stitch. Here you can view online for free Instruction Manual for a Singer 185k Sewing Machine sewingonline.co.uk/

See page 14 about the Stitch Length Regulator.

Adjusting Stitch Length in Straight Stitches:

Adjust the machine to make a range from 6 to 30 stitches within an inch (8 to 12 stitches for most projects).

Loose the first screw, lowering it to the bottom of the slot.

Then move lever until the top edge is in level with the number of desired stitches per inch.

Then raise the first screw as large as possible and tighten it. Now, set the machine to such a length that it will make the desired stitches in the forward direction.

sewingmachinebuffs.com/

As you sew, examine the stitches to see the change in tension.

If all this does not work, then most likely the stitch length mechanism is broken. This is one problem that may be a bit too much for a DIY fix. Your best choice is to hire someone to get it done.

My Singer overlocker isn't working anymore. The motor won't work at all. I've tried other foot pedals which work on my sewing machine and it still won't make any noise or whirr.

I can turn the machine on and move the needles with the hand wheel but nothing happens when I push the foot pedal. Is it the motor or maybe the foot pedal connector? Thanks!You do not say if you have just recently used it or if it has not been used in some time and these answers could help answer your question. Also, you do not say how old your machine is or if it could still be under warranty. If fairly new, I would suggest you contact whoever you purchased it from and ask for help.

These are complicated machines and your problems seem more technical that will probably need serger experienced techs to help you.

Not all repair shops have experience with these machines so I would suggest you contact this sewing forum and ask for help as they will know what questions to ask and can guide you through different steps. You will have to join but then you can go back anytime you need help.

www.quiltingboard.com/

If you need to have your machine cleaned or repaired you might contact your local Sears Service center to see if they can help. At least their repairs will be covered for up to 90 days and most repair shops do not do that.

www.service-center-locator.com/

I am asking on behalf of my mum, she has a Singer Concerto 2 Model 9217 sewing machine. Her sewing machine runs itself! It starts running when she turns it on without touching any buttons, etc. without using the pedal and it is quite fast. So out of safety she has turned it off and not used it since. I have assumed it may be an electrical problem, but I honestly have no idea with sewing machines with how they work, etc. Could anybody please point me to some sort of direction of what this could be or connected with?

This is an electrical problem - it could be a faulty connection, a broken-worn-and/or frayed wire in the foot pedal - she may not put any pressure on the foot pedal but if the problem is in the foot pedal wiring, it could easily be transmitting the wrong signal (to operate at a high speed) to the machine; or the problem could be in the machine just behind the connection point (where the foot pedal connects to the machine). There could be a crack in the connection point where the foot pedal and power cords join the machine OR the power point at the mains (wall outlet plug).

It really is not a job for the average home sewer. Most electricians or someone with some electrical skill and training should be able to find and fix the problem but it would be best if you could take the machine to a sewing machine repair technician. A sewing machine repair tech will have the skills, tools, and access to repair parts.

Until you have the machine checked by someone who really understands electricity, please do not run the machine - any user runs a very real risk of injury from the speeding needle and presser foot, or from an electrical shock.

I have a Singer 8019 model sewing machine. I need to fix the needle alinement to the center. How can I do that?

Normally to do this you will need to go to the needle bar and adjust this with a screwdriver. There is a screw on the bar that needs to be tuned in order to adjust the needle. On your machine there is a level on the front of the machine to adjust the needle position. You can find the directions on page 17 of your manual for the sewing machines. Here is a link if you do not have the manual and the instructions on how to do this. www.manualsdir.com/

On my Singer 9340, the start/stop button was depressed, even

though the foot controller was connected. Now the foot controller does not work.

You have a computerized sewing machine and doing any kind of repair, especially wiring or resetting could mess up the programs so be sure you check with an authorized repair service before changing anything or it's possible you could do untold damage to the works of your machine.

You can join this website and ask your question there as these are experienced sewing machine people and they will know what questions to ask so they will know what is happening with your machine.

www.quiltingboard.com/

Where can get or download service manuals for vintage Singer sewing machines?

There are quite a few places that offer Singer sewing machine manuals online. One of the first places that I look for the manuals is on the Singer website. If you are not having much luck to find the manual there then you can always go to different forums such as the quilting board www.quiltingboard.com/

I have a Singer Model 9217 sewing machine. It runs fine, but the light for the pattern selector is out. I can't tell which stitch it is on without testing each time. I assumed it was a simple replacement of a bulb or maybe an electrical problem, but the repairman says it is the "light board" which is no longer available.

I can't find any references to a "light board" anywhere. Could anybody please point me to some sort of direction to see if this problem can be solved?If a 'light board' is what is truly needed it is possible someone has found a way around this. You would need to contact all of the sites that sell parts for your machine to see what they tell you. If your service man is correct there may be another brand machine that would work on your machine.

www.sewingpartsonline.com/

www.singeronline.com/

You can also join the message board at Ismac's and ask your question on their site as these are people who are constantly using different parts to make their machines work.

Here is a link to the manual: (no light board is mentioned).

blessington.app.box.com/

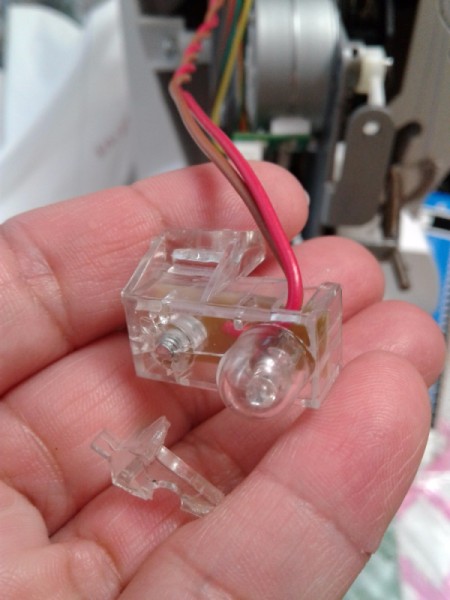

My Singer sewing machine 6199 has an error code of E7 on it. I've checked everything and I only see that the plastic part on the light has broken and the light got hung down little bit.

Does that affect the sewing machine by locked up?