I have a Jack 9100b sewing machine which is showing an error E1 on the speed adjustment screen and the needle is not moving with wheel, as well as, pedal. How can I solve this problem?

Here are the questions asked by community members. Read on to see the answers provided by the ThriftyFun community.

My Jack sewing machine is showing Eb. What to do?

After sitting for 9 months, my Memory Craft 6000 will not start. The light over the needle is on, so I know it has power.

I would have to assume it's the motherboard? Is it cheaper to repair or buy a new machine?Repair techs usually say to always first check the fuses if you're dealing with a computerized machine so maybe you can find the fuse box and take a look.

There are several very good sewing machine forums that will probably be able to help as these are machine people and they usually love to help solve problems. These members know which questions to ask to get to the 'root' of the problem and they provide instructions in 'simple' language.

You may have to join the site before asking question and occasionally may ask for pictures.

www.quiltingboard.com/

sewing.patternreview.com/

The following links are just information about the machine:

vintagesewingmachinesblog.wordpress.../

www.fiddlebase.com/

Before taking this into the repair shop I would look in your manual or even call the company to get some help with the machine. A lot of time a fuse has blown on the machine and it isn't the memory board at all. A lot of times this is so easy to fix and it might not even be the fuse. Check the bobbin winder and make sure it is pushed all the way to the right first. Now check to see if you have selected a pattern stitch and pick the length and width of the stitch. Then make sure your buttonhole is disengaged. If this isn't the issue check the fuses.

How do I resolver an E4 error on a JACK JK9100B sewing machine?

This is an issue with the bobbin shaft on the machine. It needs to be moved to the left.

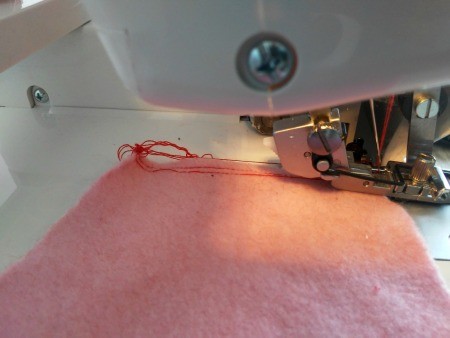

I've been using a Singer Heavy Duty 4452 sewing machine and it suddenly stopped sewing properly. It skips several stitches on the top of the fabric and the thread on the bottom is messy and bunched up, then it stops and the needle won't move until I take the fabric out.

It does this on both thick and thin fabrics. I'm not sure what the issue is or how to fix it.

Here are a few easy things to check first:

-- Is the machine threaded correctly?

-- Is the bobbin the proper size? (This is a big problem for me since I pick some up at thrift stores and garage sales; it's hard to tell with the naked eye. I finally just ordered all new ones per my machine's manual).

Checking if threading is correct is always a good starting point but it's also a good idea to check if your machine needs cleaning.

Cleaning should be set on a regular schedule according to how much you use your machine.

Does anyone know where I can get a power board for this machine. It is not 2 years old and it's failed C&C no help. I returned the first machine after 8 months because the display failed, they eventually replaced it.

When it works I love it, but I wouldn't buy again or recommendation sorry to say.If this machine was replaced recently and it has gone out again the machine should still be under warranty from the company. I would not order the power board for this machine if I were you. I'd take it back and explain to them the issue you are having with this machine and how it has already been replaced once. I would demand that they give you a different machine or different model that does not break every 6 to 9 months and needs to have the motherboard changed out in the machine.

Your machine is over 2 years old and you had to have it replaced after only having it for 8 months probably means you have no warranty left on this machine.

The only suggestions that I can make is to try asking for help at your Sears Service Center.

They may have a generic board that would work or they may tell you to toss it.

www.service-center-locator.com/

Google Butterick sewing machine repairs with your zip code and call or visit to see what they tell you about this part.

You might call or visit your local Michael's or JOANN's and ask if they know of any shop that works on Butterick machines.

My sewing machine was a gift. My foot and shank came off. Can they be reattached? The manuel was missing. Please help!

Thank You.

They should attach with a screw. If you have the make and model of your machine (there is a plate with the model and serial number on the machine) you should be able to download the manual.

This may be a simple job to someone who is familiar with working on sewing machines but can be very daunting to a beginner.

Try checking this YouTube video first but if no help then you probably need a tech to help you step by step.

www.google.com/

There are several sewing machine forums that will help you get your machine operating properly but they will need more information about your machine.

Pictures are the best because they have to know what brand of machine you have as well as approximate age.

Please take pictures of full machine (is it portable or desk or treadle?).

Take pictures of any markings/numbers/tags as these help identify your machine. Write down any numbers/names.

It will be very difficult to provide help and a manual without this information.

You will have to join each site (free) but you will be able to ask for help with any problem in the future.

www.quiltingboard.com/

sewing.patternreview.com/

ismacs.net/

I purchasd a Singer 603 sewing machine. It seems to be locked up. I plugged it in and pushed on the lever and it just humms. Is the motor shot ? Also even without it being plugged in, the the wheel will not turn.

Thanks in advance for any help. And if anyone can recommend someone here in Mooresville Indiana to work on it I'd be much appreciative. I have been using a Singer 418 since I found it last year. It is my first and it took me a while to learn to use it, but I finally got there - until I started a project with a stretchy fabric (yesterday). In the last 24 hours I learned lots about needles, puckering, thread breaking, feeding mechanism, presser feet, tension, cleaning, using the right stitches, etc. In the process I solved a few problems, but now I got stuck with one I can't solve on my own: the rotary hook stopped moving.

I have been using a Singer 418 since I found it last year. It is my first and it took me a while to learn to use it, but I finally got there - until I started a project with a stretchy fabric (yesterday). In the last 24 hours I learned lots about needles, puckering, thread breaking, feeding mechanism, presser feet, tension, cleaning, using the right stitches, etc. In the process I solved a few problems, but now I got stuck with one I can't solve on my own: the rotary hook stopped moving.

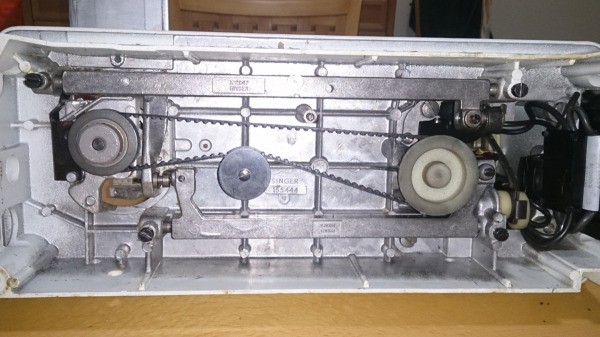

I opened the base and I can't see any broken gears or belts (see photo).

When I turn the hand wheel, the needle goes up and down normally, the feed dogs move normally, but the hook system stays still. I can move it by hand and it moves smoothly, but it would seem that the part that is supposed to engage the gears in this area is somehow not engaging, and I can't figure out what it is.

I purchased a user manual, but it doesn't cover this. The manual has a picture of the machine with the word 'Stylist' engraved on the front. My machine only has 418 on the front, it doesn't say Stylis (see photo). The bobbin case holder is different from the manual and I could not remove the bobbin case to get to the hook (last photo).

Can you help me with this? I'm not sure which of the screws around the bobbin case holder is the tension screw, but I know I must not 'screw' that! Thank you!

By Laura L.

More than likely the silicone gears have worn just enough that the rotary hook will no longer engage. That's going to be a fix for the Singer qualified repair tech - check adverts until you find the ones that say 'Singer factory trained' or 'Singer warranty service approved repairs' - no, your vintage machine is no longer under warranty but all warranty approved service techs will have been exposed to vintage AND modern machines:) The repair will cost you around $50USD (around £30 here in the UK because there are so many salvage parts machines floating about) but splash out and have your vintage machine checked over and serviced - the total for repair and service will bring it in around $90USD (£60-£75 UK).

About your user guide...click this link and go through the free downloads until you find the one that looks EXACTLY like yours:

www.singerco.com/

The '418 Stylist' was sold in Singer Sewing Centres around the world; the '418' was marketed through Sears - NOT branded as a Kenmore btw, but as a Singer 418). Because yours doesn't say Stylist, it is one of several 418 models (there were variations, a new one every year) and the above link will help you find your correct manual.

We had to remove the bobbin spindle from the winder because a bobbin got stuck. When we put it back in, the winder won't turn. The plastic disc is in place.

The spring is working, but there's nothing to turn the spindle. What needs to be attached there for it to work?Since we cannot 'see' your bobbin problem it is difficult to know if we're addressing your question correctly but maybe some of the guides presented will help you find a fix.

The most important thing to remember is that it is very easy to insert a bobbin incorrectly so be sure to start with that.

Instructions from manual:

"Check to see if your bobbin is right-side up. It is possible to put the bobbin in upside down. To fix this minor issue just take the bobbin out and put it in the right side up.

How do you tell if the bobbin is upside down? If you see only 2 little holes on the bobbin then you have it in backward. The top of the Elna bobbin has many little holes in it."

If that is not the problem then hopefully you'll find something useful on one of these sites;

sewingiscool.com/

www.youtube.com/

The following link is to a sewing forum and I have never regretted joining the group as the members are so helpful with any kind of problem so please check it out. They know what questions to ask to get straight to what is causing your problem.

www.quiltingboard.com/

I bought an Empisal 760c overlocker 3 days ago. As I was busy sewing it jammed and wouldn't sew again, please see attached images. I was sewing 2 layers of faux fur, when it jammed.

The first thing I did was to re-thread the machine and change the needles, but it is still not working. Could it be something that is out of place, maybe something troubleshooting could fix? I am desperate for assistance, I have a launch deadline month end.

Your assistance will be greatly appreciated.

Yes there is another prolem it is in your bobbin area that is causing you the issue. You need to remove the bobbin and check this area for any thread or fur that might have gotten in there. There are 2 latches on the canister of the area that need to be remove or moved over so you can remove the 2 metal pieces so you can clean out this area. Check under the feed dog to make sure there are no thread there and clean them out.

You have good instructions for cleaning your bobbin but I think you may be causing the problem with the material you are sewing as this type of material has lint and 'pieces' coming off all the time.

I would suggest you a stabilizer fabric over your material so maybe all that gunk will not stop up your machine.

If you're still having trouble or cannot understand exactly what to do I would suggest you visit a Michael's or JOANN store and see if they can recommend someone to help you.

You may have to pay a charge but it will get your machine going so you can finish your project.

Any sewing store has people that can help with this as almost all overlocker machines are very similar except maybe the threading as this is one of the most intricate things about each machine.

Sears Service Center is also a good place to ask for help and they will sometimes do the repair (one like this) while you wait - much cheaper bill.

Please think about the stabilizer as it really helps when working with this type of material.

www.nationalsewingcircle.com/

My machine would not sew, so I opened it up dusted and oiled it, now it only moves at a snail pace. Help?

By Pat A

I teach sewing here in Scotland, and do some repair-refurb on vintage machines. Your problem sounds as though it could be in the foot control - a fraying wire, 'gummy' connection or loose wire. But it could also be in the machine where the connection is made between foot control and machine. Only a trained tech will be able to quickly and relatively inexpensively determine the problem and solve it.

This really isn't a home sewer DIY. You could spend a lot of money replacing the foot control only to continue having the same problem. The best thing to do is take your machine (and foot control) to a qualified repair tech. Be sure to get an up-front estimate, and ask what a total servicing would cost, too. You'll be amazed at how well your machine sews after a proper servicing, and a good tech will give you a heads up regarding developing failures.

Word of warning - vintage sewing machine parts can be difficult to source no matter what country your machine is sewing in. Many of us techs use salvage parts we find on jumble and car boot (flea markets in the US) sales. The trouble is these parts wear out quickly, and as we can never be sure of the conditions these parts laboured under with the original machine owner, we can't vouch for the longevity of the part.

Some parts are universal (but not many) and are 'new-milled', making them a lot more reliable and a lot more expensive. Hard to find, too - a good repair tech will know where to find them, and will tell you if the replaced part is new or salvage - if he/she doesn't say, be sure to ask!

I can look at a machine and on the spot be able to advise my students if the machine is worth fixing or should be replaced by a comparable new model machine that comes with the bonus of being under warranty.

The only vintage machines worth keeping forever are the old treadle and hand crank models as those parts last centuries - I have several:)

If the machine is a 'modern vintage' (meaning it was built in the last half of the 20th century or early part of the 21st) and runs on electricity) your gran sewed your christening-graduation-wedding dress on, you may be willing to keep 'er running no matter the cost, but for the most part, after a certain point it's best to make that a display piece and buy a modern machine for reliability.

I have a big issue. Yesterday, my sewing machine jk9100b show on screen E2 and stop working. I tried all the solutions on the Internet, YouTube, nothing worked.

Can someone help me please? Big thanks!My Singer Heavy Duty 4452 sewing machine is completing a seemingly random amount of each buttonhole I try to sew. Sometimes it does the full thing, sometimes only half, part of one side, all but the end, etc. When it stops making progress, it just keeps going back and fourth in place.

The "push" lever is down and I push it back every time. Is there something I need to do for this specific problem, or is it something that more general solutions will fix? Thank you.I can suggest a couple things. Does regular zig zag stitching perform properly? If not:

---Try adjusting the tension and foot pressure to optimize your fabric and the thickness of layers.

---Try a different needle (could be bent slightly).

---Slow the stitching wayyyy down; you might be able to better discern the obstruction or what's catching that way.

If regular zig zag is ok, then you might have a bent buttonhole foot. :-( Sometimes this happens with forceful sewing on thick fabrics.

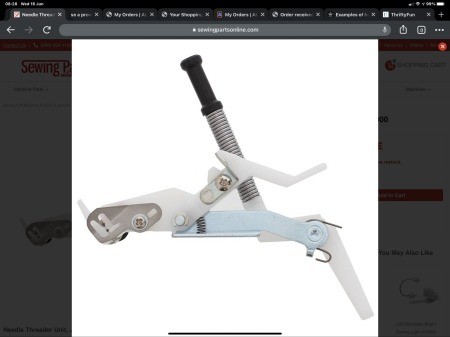

I have a sewing machine, Memory Craft 7000. I got a new replacement needle threader unit. How to put on machine, how to hold it?

If you are having trouble installing the needle threader unit, then you need the Service Manual. I found Janome Memory Craft 7000 Sewing Machine Service Manual & Parts List here (not free): www.ebay.com/

Maybe this video How to replace a needle threader will help you:

www.youtube.com/

If you have the needle threader unit installed and you have threading problems, here is the Instruction book for Memory Craft 7000 (free) www.janome.com/

I have a Brother LS-1217. I have been experiencing some difficulty sewing so I started trouble shooting and messing with the bobbin tension and such, when I found 2 springs on the left side of the bobbin winder. The larger one is attached and the smaller one is attached at the top but not at the bottom. Could this be why I'm having trouble. If so where does this little spring attach to at the bottom?

I have a Brother LS-1217. I have been experiencing some difficulty sewing so I started trouble shooting and messing with the bobbin tension and such, when I found 2 springs on the left side of the bobbin winder. The larger one is attached and the smaller one is attached at the top but not at the bottom. Could this be why I'm having trouble. If so where does this little spring attach to at the bottom?

By Kara S.

My machine was sewing fine (missing some threads, but I think that is another story!), then it makes a noise and jams a little and the needle stops going up and down. So I take out the fabric, re-thread the machine and bobbin and try again, but the needle isn't going up and down. It isn't a jam, as you can sew manually using the reel on the end of the machine.

My machine was sewing fine (missing some threads, but I think that is another story!), then it makes a noise and jams a little and the needle stops going up and down. So I take out the fabric, re-thread the machine and bobbin and try again, but the needle isn't going up and down. It isn't a jam, as you can sew manually using the reel on the end of the machine.

By Kaela

I sew primarily on Singers (modern and vintage) but the trouble you are describing is universal to most vintage electric sewing machines - sadly, you are describing a broken (or worn) bobbin gear. A Brother trained and qualified repair tech is the best person to fix your machine, in the US it will cost you around $35, in the UK around £25-30.

But when you take it in, be sure to ask the repair tech to:

A-identify the model name and number so that you can find your user guide/owner manual on the Brother website (usually a free download). Download and print it out so that you will always have it to hand when sewing.

B-give you an estimate on doing a servicing that includes not only the part and repair, but a thorough going over and clean/oiling. Yes, this will bump up the price to something like $100USD or £100GBP but is well worth it especially on a vintage electric machine like yours. An annual servicing will keep your machine running longer and find/replace parts near breaking before actual breakage and you are stopped mid project.

C-save and give you the part he/she replaces, and tell you if the replacement part is newly milled (very much preferred for longevity) or salvage (not so good, who knows the number of sewing hours on that part, and the conditions it was asked to perform under prior to salvage?!).

I used to do a lot of vintage electric Singer repair and refurbishment for my sewing students (I teach total newbies who arrive to my workshop unable to thread a needle to resew a button) but because newly milled parts for a lot of the vintage machines are so hard to come by I have given up completely on repairing and recommending them.

I still repair and refurbish non-electric machines because there is no plastic on them - parts are steel and cast iron and easy to source or refurbish if salvaged. The electric machines (all brands) went with silicone and plastic parts in the mid-60s and do not have the reliability of the metal parts.

Planned obsolence, gotta hate it!

When one of my new sewers needs a new sewing machine (usually because the vintage machine they've brought down from Mum's loft has finally sewn its last) I always urge them to buy an inexpensive but feature packed Singer, Brother, or Janome with the nearly jam-proof top-drop in bobbin system, the one-step buttonhole, and most importantly, a warranty.

Easy to use, easy to repair - important features in sewing with an electric machine. An inexpensive machine with plenty of features to keep you sewing runs from $150-200USD or £140-200GBP.

As you can see, the cost of a new machine is close enough to the cost of repairing the vintage machine to make the thought of having more features and that wonderful warranty a very good idea.

The fabric will not move, but I can pull it.

By Debbie K.

Have you checked to make sure you have not accidentally switched off the feed dogs? My machine has a switch that you turn to lower the feed dogs for free motion sewing. Check your manual or on-line manual to find yours if you are not familiar with the switch/dial/button.

Also, I have had feed dogs get clogged with fabric lint to the point they did not grab well. Brush them with a toothbrush or machine brush and vacuum to get all the stray lint out.

Good luck. If it is not one of these simple things, you could check with Brother service on-line for other ideas. They answered a query I had on my Brother serger in less than 48 hours and helped me fix the problem I was having.