I have an Usha Janome sewing machine. The thread gets cut in a few stiches. Is it a problem with tension?

The tension may be too tight, the needle may be threaded incorrectly, the thread may be old or poor quality, or the needle may need to be changed.

Here are the questions asked by community members. Read on to see the answers provided by the ThriftyFun community.

My machine is working for normal sewing, but the overlock needle bar won't move. I have changed the needle, checked all tensions, and cleaned all the dust out.

It sounds as though it's time for your New Home to have a visit with a professional repair tech. You've noted changing needle, checking tension, cleaning dust, so I'm assuming you've also followed the user manual instructions for the settings needed - after those boxes are ticked there is usually only one reason a machine won't sew - a broken or worn gear/part/assembly within the machine.

I have a New Home 532 sewing machine from 1963 and it has been the best sewing machine for me. I had it serviced about 10 years ago, but it might need it again.

I cannot get it to sew. The light is on, but it seems that the machine is not getting any power to the sewing mechanics.Referring to the owner's manual, clean and oil all the moving parts of the machine. As a machine sits unused for a long time, the moving parts seem to "gum up" and not move like they should. Cleaning out all lint, loose thread, etc, AND re-oiling should do wonders for getting your machine back to working order. Also make sure the foot pedal cord is undamaged and fully plugged in.

I had not used my Janome 7500 machine for several months. Then when I took it out to sew, it would not turn. After moving the wheel by hand using a fair amount of pressure, it moved then I was able to use it. My husband then cleaned it out and greased some of the moving parts and all was well.

There was a lot of fluff in the machine. I have now tried to use it after leaving it for a few months and it is completely frozen and I cannot get anything to move and then a beeping sound started so I have turned it off. Any ideas as to what the problem could be? Thank you.You sound like you could have a frozen motor in the machine, a belt could be broken, or you need a really good cleaning. There could be some rusted parts that are causing the machine to no longer turn. You should try once again to clean the machine. Normally the only area you are to oil is the area for the bobbin and not the rest of the machine.

Here is a couple of good videos that you can watch to help you out.

www.youtube.com/

www.youtube.com/

www.youtube.com/

I know the videos are not for your exact sewing machine but all sewing machines works the same. These are 3 different videos that will help you and your husband to get your sewing machine unstuck and working again.

First of all, I know that you should not force the wheel to turn but try to find the problem first.

I do not know what type of oil(?) your husband used when he 'greased some of the moving parts' but if he did not use genuine sewing machine oil (not WD-40 or any other type of oil) then this could be your problem.

Finding and fixing the problems can take several steps but most of the time it is best to follow a set pattern as this is the way the sewing machine techs fix problems.

Here is a very good outline - step by step - on how to unfreeze a sewing machine because this is a common problem and instructions will fit almost any machine.

sewingmachinebuffs.com/

You can also join a sewing machine forum and ask your questions there as these members are all 'techs' in the common sense of the word and help people with problems everyday.

This is a good site to keep handy as I feel sure there will be more problems in the future and this site has all sorts of information - you'll love it.

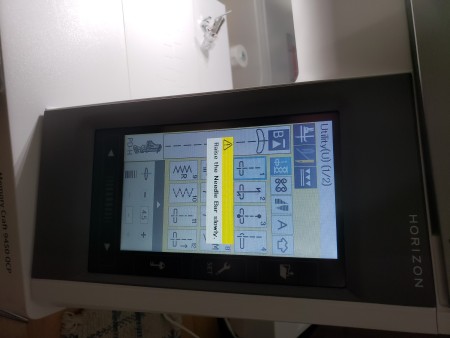

My Janome Memory Craft 9459QCP has stopped working after the needle bent during my Free Motion Quilting. I have turned it on and off several times for periods of time, and I still get this message.

It will not raise the needle. Is there a way to reboot the computer system?

I haven't used my New Home Memory Craft 7000 for a few years but got out today to do some zig zagging of edges. Thought I had threaded properly but after a few stitches, it jammed and I had to cut threads to release fabric.

Took plate off under where bobbin is and needle doesn't seem to be taking up bobbin thread. Any ideas please?This is not too hard to repair. You just have an issue of threading the machine incorrectly and not installing the bobbin in the right way. it would also help if you took apart the bobbin canister and the holder to do a good cleaning of this area before you start again. Remove all the lint and dust in his area using a small brush. Now add 1 drop of oil here and not more. Put this back together and now take your bobbin and put it back in the canister. Watch how you thread this canister to make sure the thread is moving correctly. Now put it back in the machine. Take the thread out of your machine and on all machines, they have a thread guide or arrows that can be followed. Make sure you follow the arrows. New machines are so easy to thread. Basically, you just put the thread down the right side and around the bottom and up around the arm and straight down. Now thread your needle and start again. Make sure you pull enough thread up from the bobbin and the needle to have a nice little tale at the back so that you can start sewing again.

Since you have not used your machine in several years it probably does need a good cleaning, especially the bobbin area but threading your machine properly is crucial to any type of sewing.

IIf you have your manual there is a detailed section on threading that has an excellent diagram and looks easy to follow. If you do not have your manual handy you can download a free copy from Janome - just go down page until you find your model. Janome also has some excellent videos for help with all kinds of problems and lessons.

You can also contact them for help but most of the time - if the answer is not on their site - they will only send information on where your local dealer is located.

www.manualslib.com/

www.janome.com/

Here is a video on threading but not the exact machine but I could find very little difference in the 3000 and 7000 (unless I did not know where to look).

www.youtube.com/

There are several really good sewing forums online that offer all kinds of help so you might want to think about joining some of these in case this does not solve your problem.

These members know what questions to ask and can lead you to finding how to solve almost any problem but they also have all kinds of free patterns and tips on how to do all sorts of neat things.

www.quiltingboard.com/

www.fiddlebase.com/

sewing.patternreview.com/

Is a New Home Memory Craft 7500 worth getting repaired if it says communication error?

Have you tried resetting it? Your manual would have how to reset. Also make sure it is not clogged with debris. This will hinder the machine if there is anything built up inside , therefore throwing a error code. Clean out , reset, and try again before giving in! Here is a link to others with trouble shooting - sewing.patternreview.com/

Communication error is not that hard to fix on most sewing machines. The machine could have taken a power surge or when plugged in was not connected correctly. I would start off by resetting the sewing machine. Your user manual has these instructions in the back of the book under troubleshooting. Follow the directions and reset the memory card in the machine. If this is not helping out then there could be an issue with this memory card and it may need to be replaced. I would consult a repair shop because the machine is electronic and at times it is harder to torepair at home if you don't have the experience. See how much the repair shop will charge you to replace this card.

I have a Janome DC2011 sewing machine. When I zigzag stitch, I found that the needle arm bumps into the needle threader at the highest point in a single stitch. Can I repair this myself?

You do not say how long you have had your machine or if this is the only problem you are having but if it is a 'newly' acquired machine then I would suggest you contact someone where you purchased your machine and ask for help.

If this is not possible then my next suggestion would be to contact Janome and ask for help. They will probably direct you to an area Janome dealer but they may help you if they can see your machine. I would ask for a price before letting them do anything to the machine.

If you have a Michael's or Jo Ann's near-by you could ask them if they have the name of a Janome repair person that might help you.

You can also Google Sears Service Center with your zip code for a center in your area. If you call and they are open then you can take your machine to the shop and ask for help. If everything on your machine is in good shape then you may not need for it to be serviced so just ask if they can tell you if you need a part or what do you need to do to fix it.

These are expensive machines so you should be able to find someone that can tell you what you have set up incorrectly that is causing this to happen.

There are also several sewing machine forums that will help people with problems so maybe check some of these out. You will have to join (free) to ask questions.

Sorry that I could not be of more help but this is not a machine that I ever seen or worked with.

Here is a link to a PDF manual if someone needs it.

I have the model 415 and I think you are talking about the small plastic level on the side of the needle that you pull down and put through the eye of the needle to thread the machine. if this is the case then the plastic piece is bent and this is your issue. When you lower this piece it should lower down behind the needle and then when you reach the eye of the needle you push it forward. Once the thread is on the hook you can move it backwards and lift it up. This threads the needle. The piece should be up high and towards the back and not forward. If it is forward you have an issue with the spring on the needle threader. You may have a bent spring that needs to be replaced. You can try and remove the screw on the side and take a look at this one. It sounds like this piece needs to be replaced.

I am restoring to working order, my wife's great aunt's New Home Treadle Sewing Machine. It is missing the spring loaded part that locks the handwheel to the belt pully.

I can use a small bolt to lock these two together, but when would one wish to uncouple the handwheel from the belt pulley?I believe it would be best to replace the spring as most of the time, vintage machines did not have 'unnecessary' pieces/parts.

If working on sewing machines is a new hobby for you it may be a good idea for you to join one of the sewing machine groups that have a lot of knowledgeable sewing machine people that can help you with any problems you may have now or in the future.

These members can help you find parts or make a part if none are available as they are usually in contact with other sites that help you if they cannot.

I have found belonging to these groups can save me so much time and frustration and your wife will also be interested in belonging as they have so many useful tips and free patterns and on and on...

It is free to join so please check out these sites:

www.quiltingboard.com/

www.helenhowes-sewingmachines.co.../

groups.io/

My New Home 6000 sewing machine only sews in reverse. How do I fix this? Thank you.

Your reverse level is stuck in the down position and is not moving so the machine can go forward and not reverse. You'll need to check the level and if you can't get it unstuck from the outside of the machine you'll need to remove the cover and check the level from the inside. A lot of time a small drop of oil can cure this problem or there could be a broken part that is causing this.

I have a Janome Memory Craft 4800. After cleaning out all of the packed in lint from the feed dogs, bobbin holder, hook race, and changing my needle, the bobbin thread still gets bunched up. Can this be fixed from home?

By Susan B

Probably not.

I do some sewing machine repair (I'm self-taught) for my sewing students and from your description it sounds as though a part inside the machine has either broken/worn, or become mis-aligned.

Only someone with training (preferably factory or a course), experience, and the proper tools will be able to open the machine, find and resolve the problem, and then put the machine back together in a way that means the machine will operate properly.

I have a Janome My Excel 4023. The stitch select dial turns along with the stitch display, but machine will only sew a straight stitch.

I own one of these machine and normally there are 3 setting that need to be set to get it to do the other stitches. There is one dial that you set the letter on, the second dial you set the stick design on and the thrid one is the level that tells you the stitch size. After setting all of these and the machine will still not do the correct stitch there is an issue with the arm of the machine. You can try opening up the case of the machine and putting a drop of oil on some of the parts to see if this will help. Other than this there is a part inside the machine that is broken and should be repaired.

Can you help with my problem? I have stripped and serviced my New Home SS2015 machine, but I need to know the correct position when the needle is down in relation to the bobbin unit. On zig zag it is only doing a straight stitch as not picking up thread on one of the down positions of the needle.

I have tried moving the belt onto a different cog, but nothing seems to work. The needle does go zig zag. The pics show both positions of the needle on zig zag. Thank you.

You may have to contact Janome (New Home) and ask for help. They may have a video as you must be trying to work this out without really knowing the correct procedure.

This is also a forum and they try to help people with troubleshooting their machines.

sewing.patternreview.com/

thevillagehaberdashery.co.uk/

It's possible someone on this site could help you but it's a good link to keep as they have all the accessorizes/parts for this machine.

www.sewingpartsonline.com/

Occasionally Michaels or JoAnns Craft stores have names of Janome shots and if all else fails you may have to take it a shop.

Also, Sears Service Centers usually have someone on site that can do minor repairs or adjustments to any brand sewing machine and they will not charge as much money as a regular repair shop. Google Sears Service with your zip to find their location.

Just in case someone needs it - here is a free copy of a manual for this machine. You can find different manuals online but most will cost 'something'.

www.janome.com/

I have a Janome MC6000 machine. While sewing the balance wheel stalled and then only spun after that. Did I strip gears or break a belt? I can still manually raise and lower the needle.

It does not sound like you have stripped a gear on the machine if you can still lower and raise the needle using the wheel. It sounds more like a connection problem that the wheel is not engaging correctly so that when you supply power to the machine the wheel turns automatically to raise and lower the needle. You may need to take the machine into a repair shop to have it fixed. They may need to open the machine to adjust the wheel and the tension. The belt could also be old and slipping on the machine.

I have a Janome 12000 that needs a new motherboard. Is it worth fixing?

I have an New Home Memory Craft 7500. The drive belt broke, can the machine be opened to replace the belt without issues to the computer or mother board?

It is not that difficult to do this. You will need to unplug your sewing machine first. Now remove the cover on the sewing machine so you can see the drive belt. The drive belt uses screws to keep the tension on the belt. These screws will need to be loosened in order to free up the belt so that you can install a new one. Now replace the belt and tighten up the screws. Here is a video that shows the details on how to do this. www.youtube.com/

I know this is not your exact machine but all sewing machine work basically the same and you can follow these instructions to change your drive belt.

I have a New Home sx2122 sewing machine. Can anyone help me find out when it was manufactured? I have had it since it was new, but I've had it that long and I can't put a date on it. Also are parts still available for my beloved machine?

Thank you.

I believe the first year your machine was made was in 1987 but not sure if they continued to other years.

These machines seem to be identical.

New Home and Janome SX2122 - just a different name plate so any part that fits Janome should also fit your machine.

You did not mention needing a manual but here is a link to a PDF if one is needed. There does not seem to be free one but this one is only $4.99 and all other sites seem to be over $10. You can also order a hard copy.

Parts can probably be ordered from any local shops that sell Janome but check out prices online also.

www.sewingmachinesplus.com/

You do not show a picture of your machine but this appears to be one like yours.

www.ebay.com.au/

If you have further questions - or problems - you can contact someone on this site. You'll have to join (free) but you'll love it as they have so many things for sewing you'll be looking for hours.

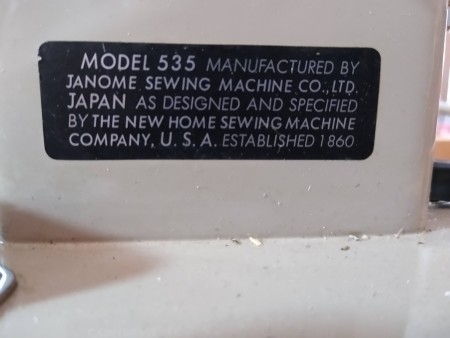

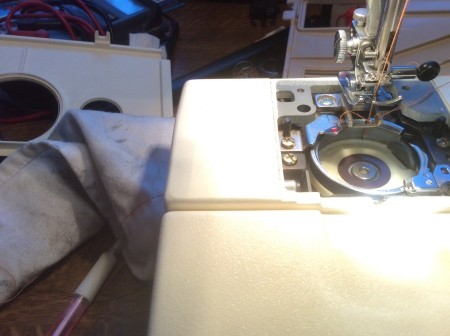

I have recently acquired a 535 New Home Janome sewing machine. How do I adjust the needle position so that it is in the centre?

It is sewing fine, but the needle is to the left as shown in the picture.

Thank you.